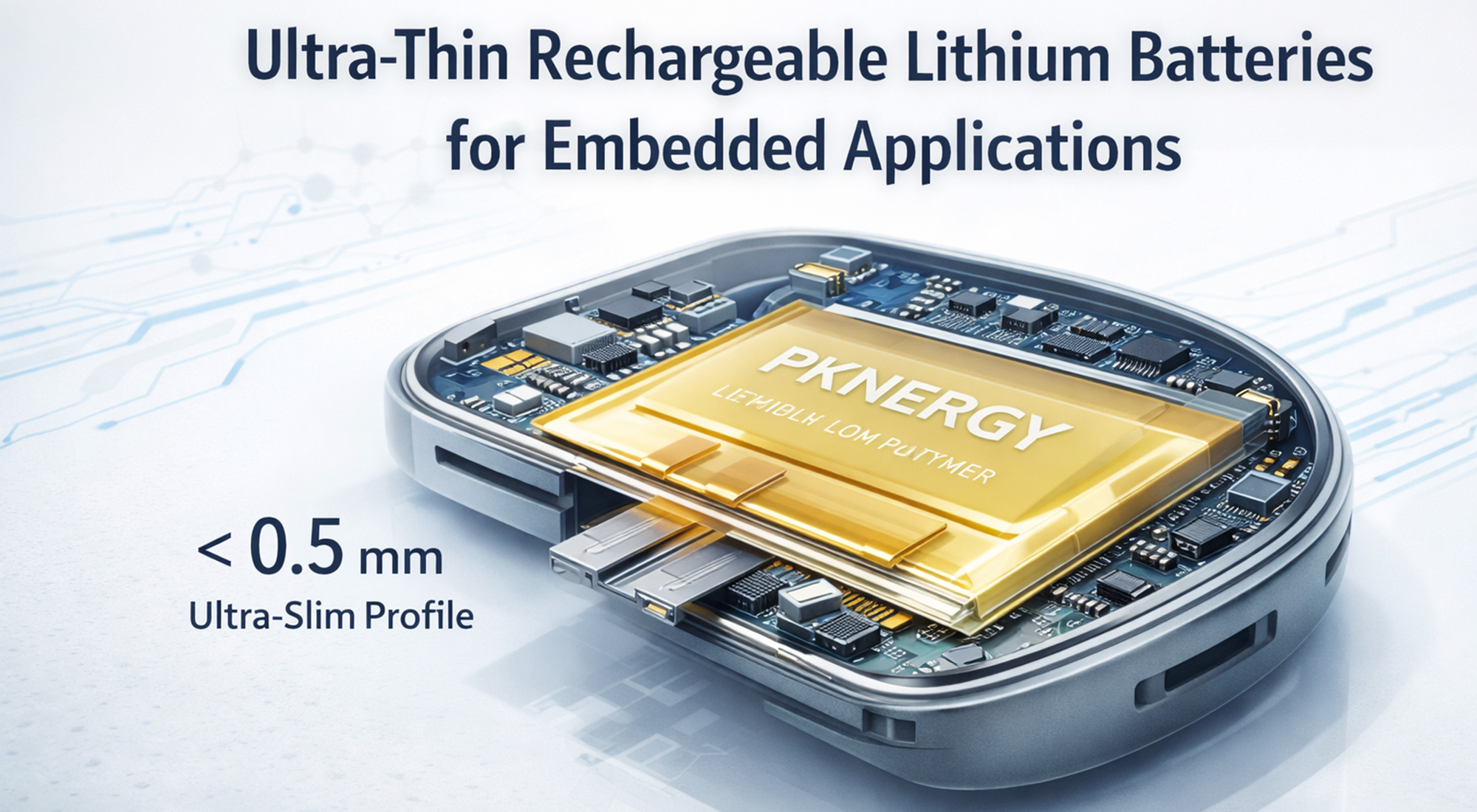

Ultra-Thin Rechargeable Lithium Batteries for Embedded High-Safety Applications

Ultra-slim (

Overview

As electronic products continue to shrink while performance expectations rise, power solutions are facing unprecedented design challenges. One of the most demanding requirements today is the development of ultra-thin rechargeable lithium batteries that combine minimal thickness, stable capacity, long-term reliability, and high safety—especially for fully embedded applications.

If your product requires a purpose-built form factor, PKNERGY can support rapid development through our Custom Lithium Polymer Battery program and broader custom lithium battery solutions.

Why Ultra-Thin Batteries Matter

In applications such as embedded SOW crystals, smart materials, micro-sensors, and precision electronic components, space is extremely limited. Traditional coin cells or standard Li-ion batteries are often too thick, rigid, or unsafe for long-term integration.

Ultra-thin rechargeable lithium batteries offer several critical advantages:

- Thickness below 0.5 mm, enabling seamless integration into ultra-compact structures

- Customizable form factors for non-standard product designs

- Rechargeability for extended service life

- Lower weight and improved mechanical flexibility

These characteristics are especially valuable for next-generation wearable and embedded systems. Related solution reference: Ultra-thin Battery for Wearables.

Typical Design Requirements

A representative ultra-thin battery design may include:

- Dimensions: ~38.0 × 27.0 mm

- Thickness: ≤ 0.45 mm

- Capacity: ~20 mAh

- Application: Fully embedded power supply

- Safety: High thermal and mechanical stability

- Operating temperature target: Extended range beyond standard lithium batteries

For projects that need strict thickness control, flexible tab routing, or special encapsulation, PKNERGY can customize pouch structure and protection design via custom Li-Po development.

Engineering Challenges in Ultra-Thin Battery Design

Reducing battery thickness to below 0.45 mm significantly limits electrode loading and internal structure options. Achieving usable capacity at this thickness requires advanced materials, precise process control, and extensive engineering validation.

For embedded high-safety applications, additional engineering considerations often include:

- Mechanical stress and bend tolerance inside rigid/laminated structures

- Thermal stability under continuous micro-load and charging conditions

- Long-term reliability for products with multi-year service expectations

- Safety design integration (over-charge/over-discharge/short-circuit protection)

When embedded into equipment for field use, similar reliability requirements are seen in industrial automation and portable detection devices.

Customization as the Key Solution

Off-the-shelf batteries rarely meet ultra-thin embedded requirements. A custom battery development approach allows engineers to optimize thickness, capacity, and safety simultaneously while maintaining reliability.

Off-the-shelf vs. Custom ultra-thin battery

| Requirement | Off-the-shelf Battery | PKNERGY Custom Solution |

|---|---|---|

| ≤0.45 mm thickness | Often not available | Designed to target thickness |

| Non-standard shape | Limited choices | Custom outline & tabs |

| Embedded safety | Generic protection | Application-specific protection strategy |

| Lifecycle consistency | Varies by batch | Engineering validation & controlled process |

If you’re developing an embedded product roadmap, you can start with a quick requirements checklist via our FAQ or request a quote directly: Contact Us.

The Future of Ultra-Thin Rechargeable Batteries

Advances in materials science and manufacturing precision continue to push the limits of ultra-thin rechargeable lithium batteries, enabling new generations of embedded, high-reliability electronic products.

As devices move toward tighter integration and smarter connectivity, ultra-thin lithium solutions will become increasingly important across IoT, medical, and industrial segments—especially where weight, thickness, and safety are non-negotiable.

Related application references: Medical Device Power Solution · Consumer Electronics Power Solution · Security Devices Power Solution.

About PKNERGY ENERGY

PKNERGY ENERGY specializes in custom lithium battery solutions, including ultra-thin LiPo and Li-ion batteries for embedded, IoT, medical, and industrial applications.

Learn more: About Us · Explore customization: Custom Lithium Polymer Battery.

FAQ

How thin can a rechargeable lithium battery be for embedded products?

Ultra-thin rechargeable lithium batteries can be designed below 0.5 mm, and in some embedded applications thickness targets such as ≤0.45 mm are achievable depending on capacity, materials, and structure design.

Can ultra-thin batteries be customized to non-standard shapes?

Yes. Ultra-thin Li-Po batteries are often customized in outline, thickness, tab position, wiring, and protection strategy to match embedded product constraints. See custom Li-Po options.

What safety protections are important for embedded high-safety applications?

Typical protections include overcharge, over-discharge, and short-circuit prevention, plus application-specific thermal/mechanical safety design depending on the embedded structure and operating environment.

How do I request a custom ultra-thin battery from PKNERGY?

Share your target dimensions, thickness, capacity, voltage, operating temperature range, and usage profile. You can submit requirements via Contact Us.

Contact Jennifer — PKNERGY

Need an ultra-thin rechargeable lithium battery for embedded high-safety products? Send your size and performance targets—we’ll recommend a custom solution.

Post time: Dec-23-2025