|

Industrial Safety Battery • Gas Detection

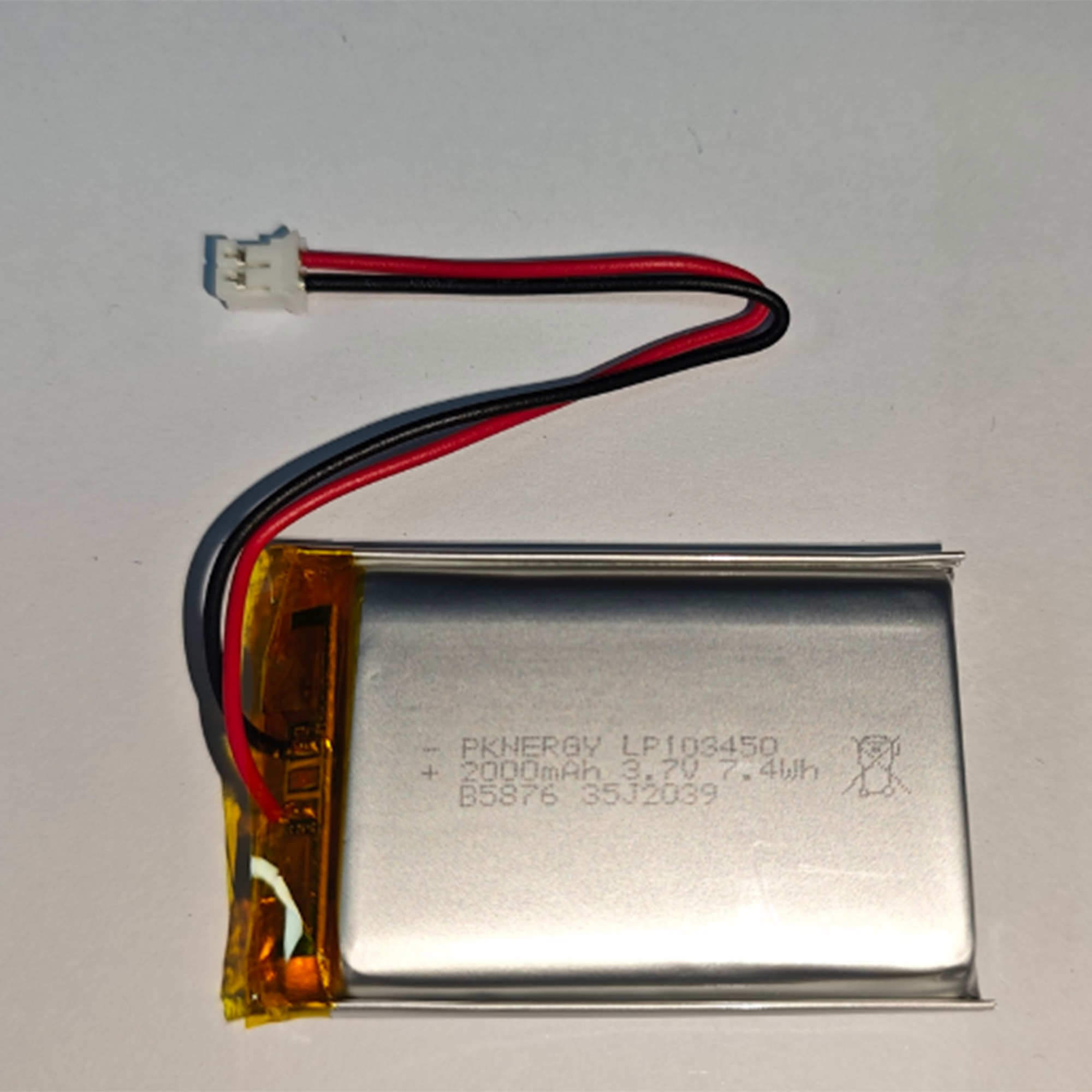

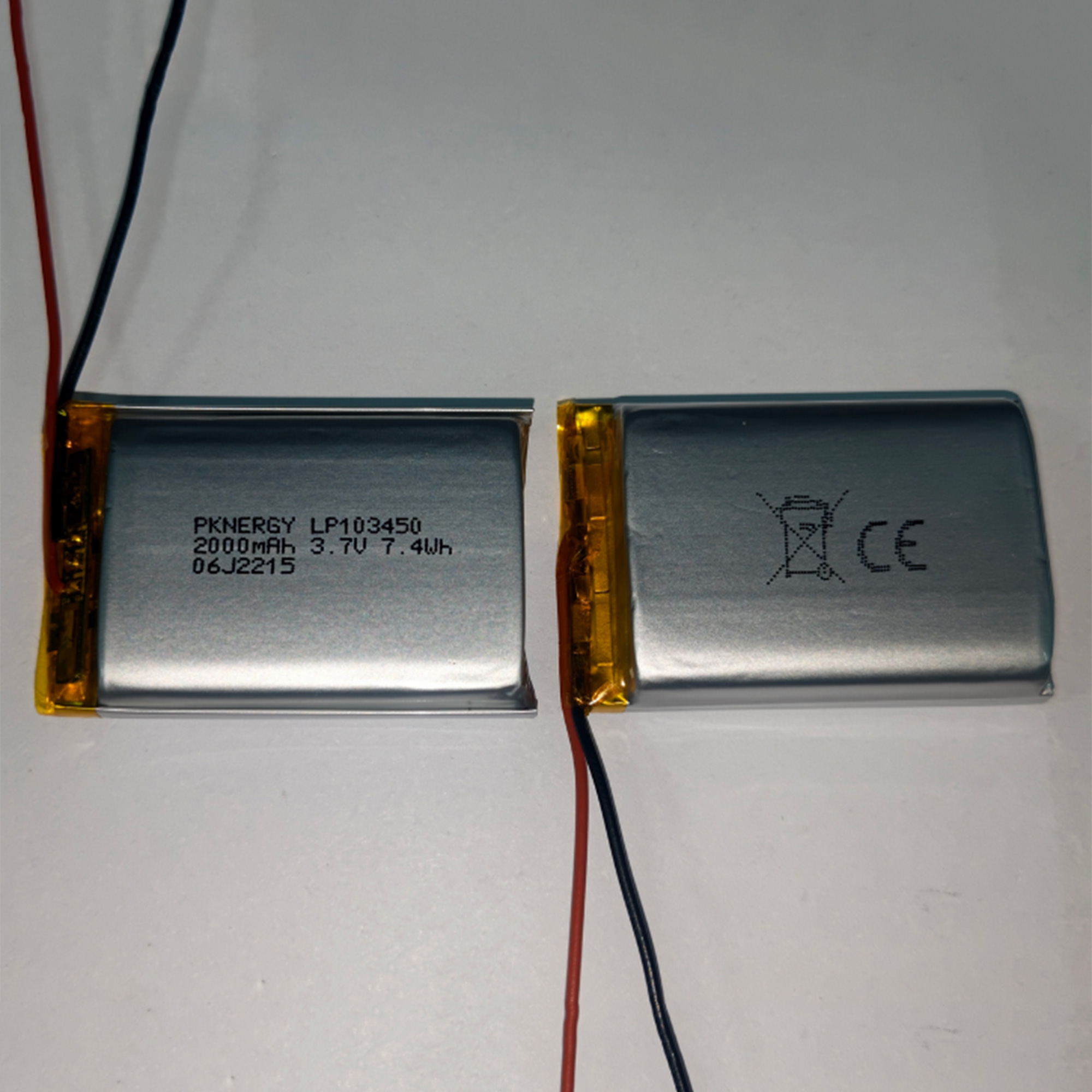

Multigas Detector Battery Pack (3.7V 2000mAh) for Industrial Safety MonitoringA compact lithium battery solution engineered for portable multigas detectors—stable 3.7V output, long runtime, and safety-focused protection design for field inspection and confined-space monitoring.

Replace image URLs in the <img> tags anytime to update visuals.

|

Product photo: portable multigas detector in industrial safety scenario. Product photo: portable multigas detector in industrial safety scenario. |

1) Project Snapshot

|

Device

Portable multigas detector for industrial inspection and confined-space monitoring.

|

Battery Goal

Stable power for sensors + alerts, longer runtime, compact fit, and high safety.

|

PKNERGY Customization

Pack dimension tuning, connector matching, and protection strategy for field reliability.

|

Gas detection instruments often run in safety-critical environments where stable power directly impacts sensor accuracy, alarm response, and overall reliability. This solution focuses on consistent output, safe protection, and practical integration for portable instruments.

2) Market & Use Case Trends

Compared to consumer electronics, portable gas detectors prioritize reliability and safety: stable voltage for sensors, predictable runtime for shift work, and protection design suitable for field environments.

3) Battery Requirements for Multigas Detectors

Electrical performance

|

Mechanical & safety constraints

|

4) How the Battery Is Integrated

- Location: internal battery compartment

- Role: primary power source for sensors, alarms, and communication module

- Key engineering point: maintain stable voltage during continuous sensing + alarm bursts

For tight mechanical integration, PKNERGY typically customizes the pack outline, connector type, cable length, and protection thresholds through

customized battery solutions.

5) Pain Points Solved (Problem → Solution → Result)

PKNERGY solution: capacity matching + low-power optimization aligned to sensor duty cycle (project-dependent).

Result: longer operation per charge and fewer mid-shift power interruptions.

PKNERGY solution: cell/pack IR control + tuned protection + harness verification for contact stability.

Result: more stable sensing and more reliable alarm response.

PKNERGY solution: pack outline customization + connector/cable customization for production assembly.

Result: faster installation and fewer field failures caused by poor contacts.

6) Battery Parameters (Reference)

7) Safety & Reliability

|

Protection strategy

|

Field reliability

|

8) Topic Cluster Links (Old Website)

9) FAQs

How long can a 3.7V 2000mAh battery run a multigas detector?

Why does voltage stability matter for gas sensing?

Can you customize the connector and cable length?

What safety protections are included?

Do you support sampling and OEM mass production?

10) Contact Jennifer — PKNERGY

Need a battery solution for portable gas detection instruments? Share your device voltage, peak current, and housing size—PKNERGY will propose a stable and production-ready pack.

Email: sale3@pknergy.com

Post time: Feb-05-2026