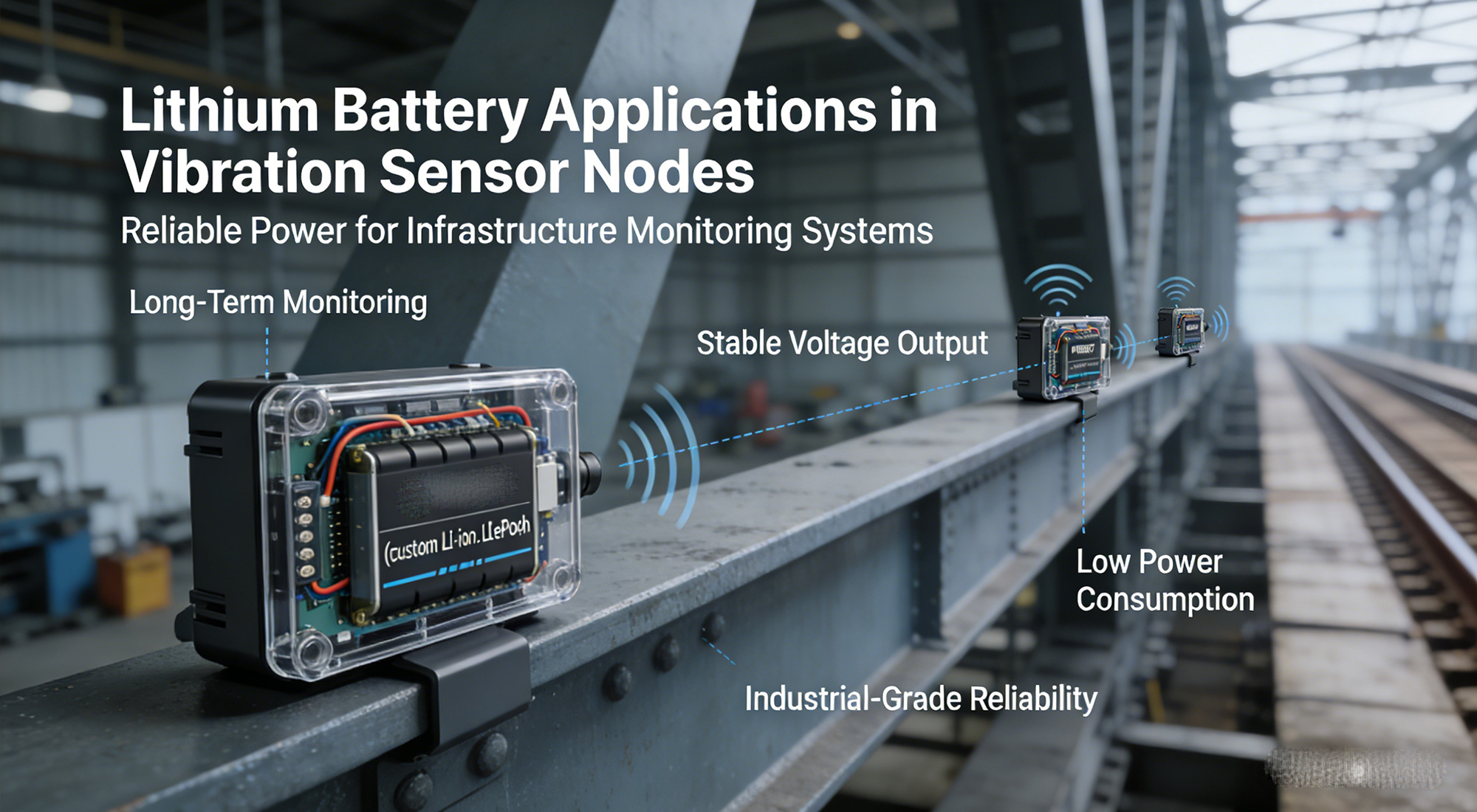

Lithium Battery Applications in Vibration Sensor Nodes for Infrastructure Monitoring

Reliable lithium power solutions for long-term vibration monitoring and predictive maintenance

Infrastructure Monitoring · Vibration Sensor · Lithium Battery

Industry Background

Vibration sensor nodes are widely used in infrastructure monitoring to detect structural changes,

mechanical faults, and abnormal operating conditions. Typical applications include bridges,

railways, industrial equipment, and smart buildings.

As smart infrastructure and predictive maintenance systems become more prevalent, vibration

monitoring networks are increasingly deployed in distributed environments where wiring is

impractical or costly. In these scenarios, battery-powered operation becomes the preferred solution.

Compared with traditional power options, lithium batteries offer higher energy density and longer

service life, making them ideal for remote monitoring systems and

industrial automation battery solutions

.

Power Requirements of Vibration Sensor Nodes

Vibration sensors and data acquisition modules require stable and clean power to ensure measurement

accuracy. While most sensor nodes remain in ultra-low-power standby mode, they periodically activate

sensors, processors, and wireless transmitters.

This operating pattern means batteries must support both low average current consumption and short

bursts of peak discharge. Poor battery selection can lead to voltage instability, data loss, or

reduced sensor accuracy.

Benefits of Lithium Battery Technology

Lithium battery technology provides an optimal balance between performance, size, and reliability

for vibration sensor nodes.

- High energy density enabling compact battery pack design

- Stable discharge voltage for accurate sensor measurement

- Long cycle life and low self-discharge for multi-year operation

- Reduced maintenance frequency across large-scale deployments

These advantages make lithium batteries a preferred choice for

custom lithium battery packs

used in monitoring and sensing equipment.

Reliability and Safety Considerations

In infrastructure monitoring applications, system reliability is critical. Battery failure can

result in data gaps, missed fault detection, or increased maintenance costs.

Lithium battery packs for vibration sensor nodes are typically designed with integrated protection

circuits, including overcharge, over-discharge, and short-circuit protection. High-quality cells

combined with consistent manufacturing processes further enhance long-term stability and safety.

Charging and Maintenance Strategies

Some vibration monitoring systems integrate energy harvesting methods such as solar power or

vibration energy harvesting. Lithium batteries work effectively as energy buffers in these hybrid

systems, storing harvested energy and delivering stable output to sensor electronics.

Their predictable performance simplifies maintenance planning and reduces the total cost of

ownership for infrastructure operators.

PKNERGY’s Expertise in Sensor Battery Solutions

PKNERGY provides customized lithium battery solutions for vibration sensor nodes used in

infrastructure monitoring, industrial equipment diagnostics, and smart building systems.

Our capabilities include cell selection, pack structure design, BMS integration, and

environmental adaptation. Learn more about our

custom LiFePO4 battery solutions

for high-reliability applications.

Post time: Feb-04-2026