Li-Polymer · Lightweight

Drone / UAV

Customer Case: Lightweight 7.4V Li-Polymer Battery Pack for Stable UAV Power Delivery

A small drone manufacturer needed a compact battery that would not compromise flight stability due to weight,

while still delivering reliable power during takeoff, maneuvering, and hovering. PKNERGY provided a lightweight

7.4V 500mAh Li-polymer pack designed for consistent performance and easy integration into a space-constrained airframe.

power consistency during takeoff and maneuvering. We focused on compact integration and stable discharge behavior.

Compact fit

Stable power

Production-ready

Customer Profile (Anonymous) & Project Context

The customer is a drone/UAV manufacturer focusing on compact, lightweight platforms. Due to confidentiality, we do not disclose the company name.

Their engineering team needed a battery solution that could be integrated into a fixed airframe space while maintaining stable power output

during dynamic flight phases.

Challenges (What the customer needed to solve)

The customer needed a lightweight pack that still delivered usable runtime.

control anomalies, or unexpected resets in sensitive electronics.

to integrate without mechanical redesign.

We recommend validating voltage behavior under peak demand, connector reliability, and consistent batch performance.

Solution (How PKNERGY supported the project)

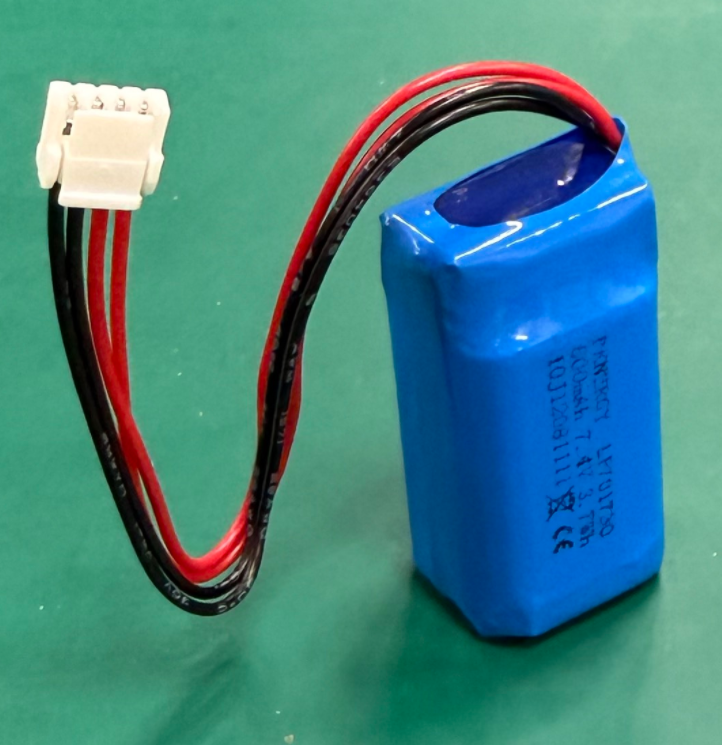

PKNERGY proposed a compact 2S Li-polymer pack (LP701730) for the UAV power module. The design focused on lightweight integration,

stable discharge behavior, and production-ready consistency for future batch supply.

Technical Specifications

Discharge: -20–0°C (0.2C) · 0–10°C (0.5C) · 10–35°C (2C) · 35–60°C (0.5C)

Results & Customer Feedback

- Improved flight stability: lightweight pack helped maintain balance and responsiveness.

- Reliable power delivery: stable output supported takeoff, maneuvering, and hovering.

- Faster integration: compact format and connector readiness reduced redesign effort.

- Production confidence: consistent parameters and cycle life aligned with batch delivery needs.

PKNERGY’s solution fit our space perfectly and delivered consistent performance during testing.”

Photo Gallery (Optional)

Replace each image URL with your WordPress Media Library link. Duplicate or remove cards freely.

FAQ — Common Questions

Our engineers will propose a production-ready battery solution.

Post time: Dec-30-2025