Ultra-Low IR · High Discharge

Power / Drone

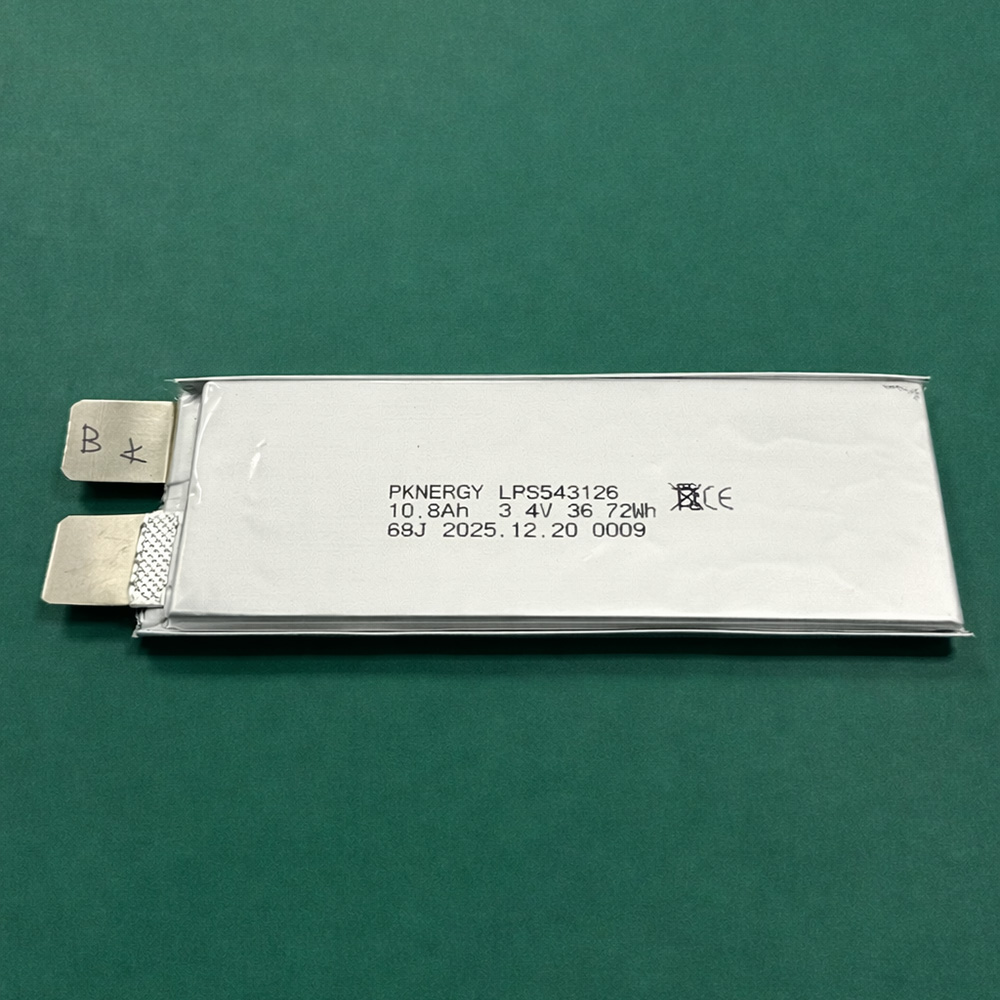

3.4V 10.8Ah High-Discharge Li-Po Cell for Power Equipment & Drone High-Load Scenarios

A customer developing high-load power equipment and drone-related systems required a lithium polymer solution with

very low internal resistance and high continuous discharge to avoid voltage drop under peak demand.

PKNERGY delivered the LP8543126 cell (3.4V 10800mAh), validated for 50A continuous discharge with

controlled IR and clear temperature usage guidance to support stable performance and production consistency.

We focused on low IR screening, discharge stability, and clear operating temperature guidance for real-world deployment.

≤ 5mΩ low IR

Stable under load

Production screening

Introducing the Customer (Anonymous) & Their Journey

The customer is a system integrator working on high-power lithium solutions for power equipment and drone-related platforms.

Due to confidentiality, we do not disclose the company name. For this case study, the project contact is described as a realistic anonymous profile.

Charge: 10°C to 35°C (recommended)

while maintaining clear safety margins and production-ready consistency.

Challenges (What was going wrong)

This may reduce thrust/torque output and can trigger system protection.

to support safe, repeatable performance.

The customer required stable supply quality and screening criteria.

We recommend validating voltage behavior under peak load and setting QC limits to reduce field variation.

The solution emphasized ultra-low IR control, stable discharge behavior, and clear charging/discharging limits to support

both engineering validation and future production supply.

Technical Specifications

Discharge Temperature: -20–0°C (0.2C) · 0–10°C (0.5C) · 10–35°C (50A) · 35–60°C (0.5C)

Results & Customer Feedback

- Reduced voltage sag: low IR cell behavior improved stability under high discharge.

- Higher peak-load confidence: stable output supported demanding power scenarios.

- Clear operating window: temperature and cut-off guidance reduced misuse risk.

- Batch consistency: screening targets supported repeatability for future supply.

stabilize performance during high-load tests, and the technical guidance made integration much easier.”

Photo Gallery (Optional)

Replace each image URL with your WordPress Media Library link. Duplicate or remove cards freely.

FAQ — Common Questions

Our engineers will propose a production-ready cell/pack solution.

Post time: Jan-06-2026