Payment / POS Terminal

Stable Runtime

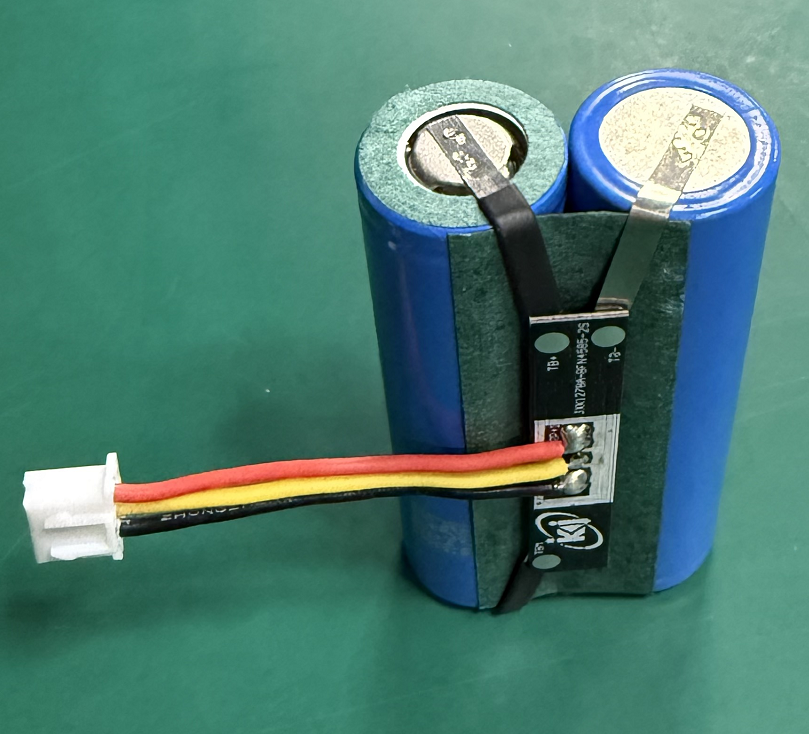

7.4V 2600mAh INR18650 Battery Pack for Portable POS Terminals

A POS terminal customer needed a rechargeable pack that could power handheld payment devices with

stable output, safe charge/discharge limits, and reliable batch consistency.

PKNERGY supplied a compact 7.4V 2600mAh (2S) INR18650 pack designed for frequent daily charging and

steady performance during payment processing, receipt printing, and wireless communication load.

We focused on stable voltage, safe thresholds, and connector/harness reliability for production use.

Stable output

8.4V / 6.0V thresholds

Connector reliability

Introducing the Customer (Anonymous) & Their Journey

The customer is a POS device manufacturer supplying handheld payment terminals to retailers and service businesses.

Due to confidentiality, we do not disclose the company name. For this case study, the project representative is described as a realistic anonymous profile.

Charge: 10°C to 35°C (recommended)

and reduce after-sales issues caused by unstable battery performance.

Challenges (What the customer needed to solve)

The battery must handle short peaks without brownout or restart.

We recommend validating voltage under print peaks and aligning QC on harness/connector consistency.

Solution (How PKNERGY engineered it)

PKNERGY supplied a 2S INR18650 pack built around stable daily-use needs: controlled internal resistance, clear cut-off limits,

and production-ready harness/connector quality to withstand repeated handling and docking.

Technical Specifications

Discharge Temperature: -20–0°C (0.2C) · 0–10°C (0.5C) · 10–35°C (3A) · 35–60°C (0.5C)

Results & Customer Feedback

- Fewer device resets: stable output reduced brownout during peak usage events.

- Safer daily charging: clear thresholds and stable charging behavior improved reliability.

- Lower after-sales issues: harness/connector QC reduced loose-contact faults.

- Batch repeatability: consistent assembly supported production supply.

PKNERGY helped us improve reliability with stable output and solid connector quality, reducing our after-sales issues.”

Photo Gallery (Optional)

Replace each image URL with your WordPress Media Library link. Duplicate or remove cards freely.

FAQ — Common Questions

Our engineers will propose a production-ready battery solution.

Post time: Jan-06-2026