Li-ion 21700 · High Capacity

Hand Sanitizer Dispenser

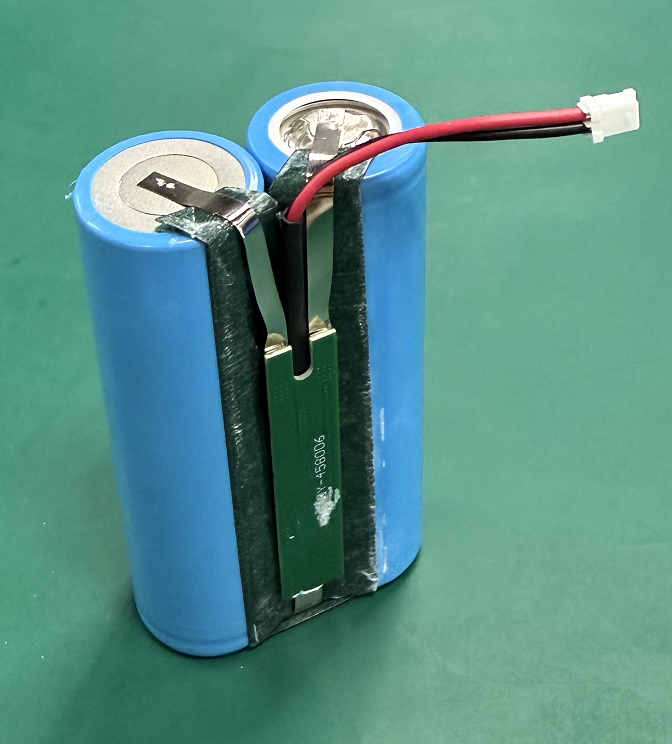

7.4V 5000mAh 21700 Battery Pack for Reliable High-Usage Hand Sanitizer Dispensers

A hand sanitizer dispenser manufacturer needed a battery solution for high-traffic environments such as offices, schools,

and public facilities. Their priority was long runtime, stable motor/solenoid drive, and consistent performance

in daily repeated dispensing cycles. PKNERGY delivered a compact, high-capacity 2S 21700 pack that supports continuous use and reduces maintenance frequency.

We optimized this pack for long runtime, stable output under repeated pulse loads, and production-ready assembly.

10A discharge

Stable repeated cycles

Production-ready

Customer Profile (Anonymous) & Project Context

The customer is a manufacturer of automatic hand sanitizer dispensers for high-usage environments.

Due to confidentiality, we do not disclose the company name. Their device uses a small motor/solenoid mechanism,

requiring reliable power pulses and stable voltage across frequent daily dispensing cycles.

Challenges (What the customer needed to solve)

The customer needed higher capacity to extend service intervals.

leading to weak dispensing or intermittent failures.

operating window for charge/discharge and temperature guidance.

and practical batch consistency to reduce field failures.

Solution (How PKNERGY engineered the pack)

PKNERGY delivered a 2S 21700-based battery pack designed for hand sanitizer dispensers that operate continuously throughout the day.

The solution focused on extending runtime, ensuring stable pulse output, and maintaining batch consistency for production delivery.

Technical Specifications

Charge: 0–10°C (0.2C) · 10–35°C (1C) · 35–45°C (0.5C)

Discharge: -20–0°C (0.2C) · 0–10°C (0.5C) · 10–35°C (2C) · 35–60°C (0.5C)

Results & Customer Feedback

- Extended uptime: higher capacity reduced battery swaps and charging frequency.

- Consistent dispensing: stable output improved actuation consistency and user experience.

- Higher reliability in busy areas: reduced intermittent failures under repeated pulse loads.

- Production readiness: clear operating window and batch consistency supported deployment.

PKNERGY helped us improve consistency and reduce maintenance frequency during real deployment.”

Photo Gallery (Optional)

Add as many images as needed (battery photos, installation details, testing photos, etc.). Duplicate or remove cards freely.

FAQ — Common Questions

Our engineers will propose a production-ready battery solution.

Post time: Jan-05-2026