Li-Polymer · High-Rate

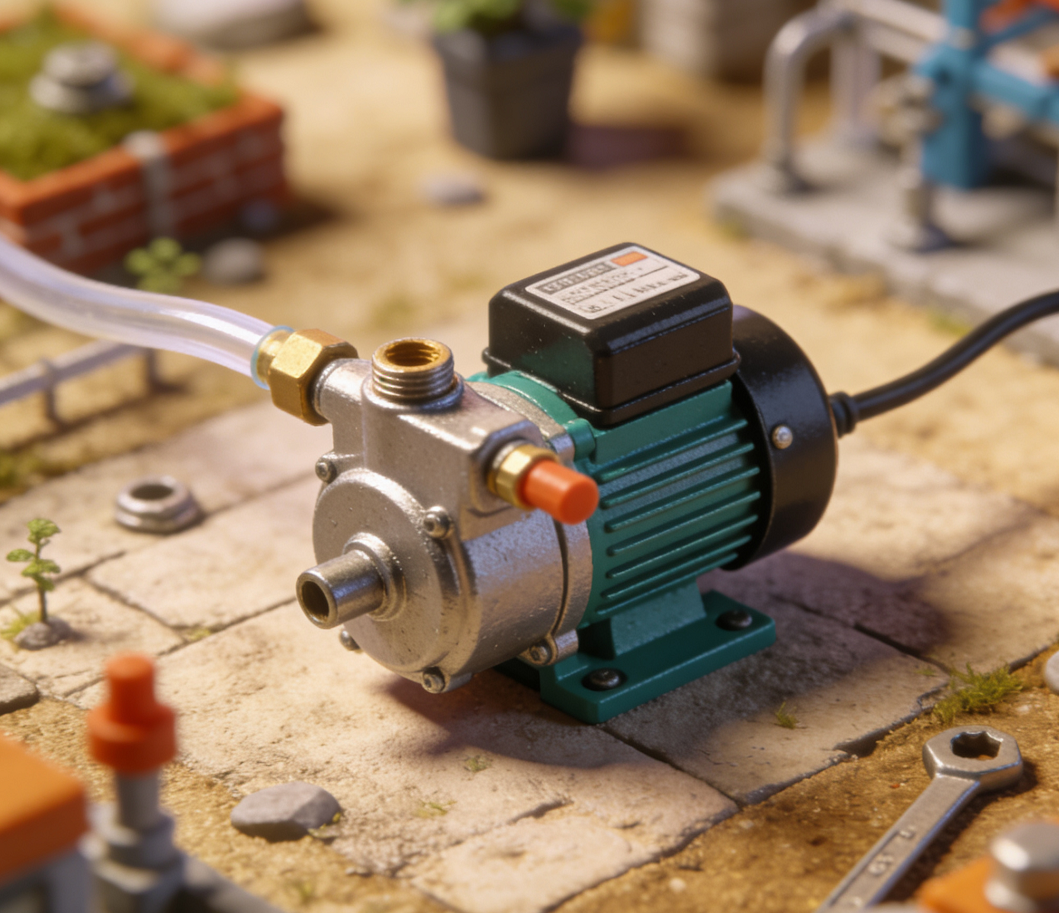

Mini Pump

Customer Case: 22.2V High-Rate Li-Polymer Battery for Compact Mini Pump

A mini pump manufacturer needed a battery that could fit a tight enclosure and still handle motor startup surge current.

Previous solutions caused voltage sag and occasional shutdown. PKNERGY delivered a compact, high-rate Li-polymer pack designed

for stable startup behavior and consistent batch performance—ready for production integration.

around rate capability + IR control + consistent thresholds for production use.

Introducing the Customer (Anonymous) & Their Journey

Our end-user is a mini pump equipment manufacturer serving compact fluid-transfer applications. Due to confidentiality,

we do not disclose the company name. However, we can share the engineering journey:

after multiple rounds of trial packs and supplier samples, the team still faced inconsistent startup behavior and production risk—

prompting them to seek a compact, high-rate, stable-voltage solution.

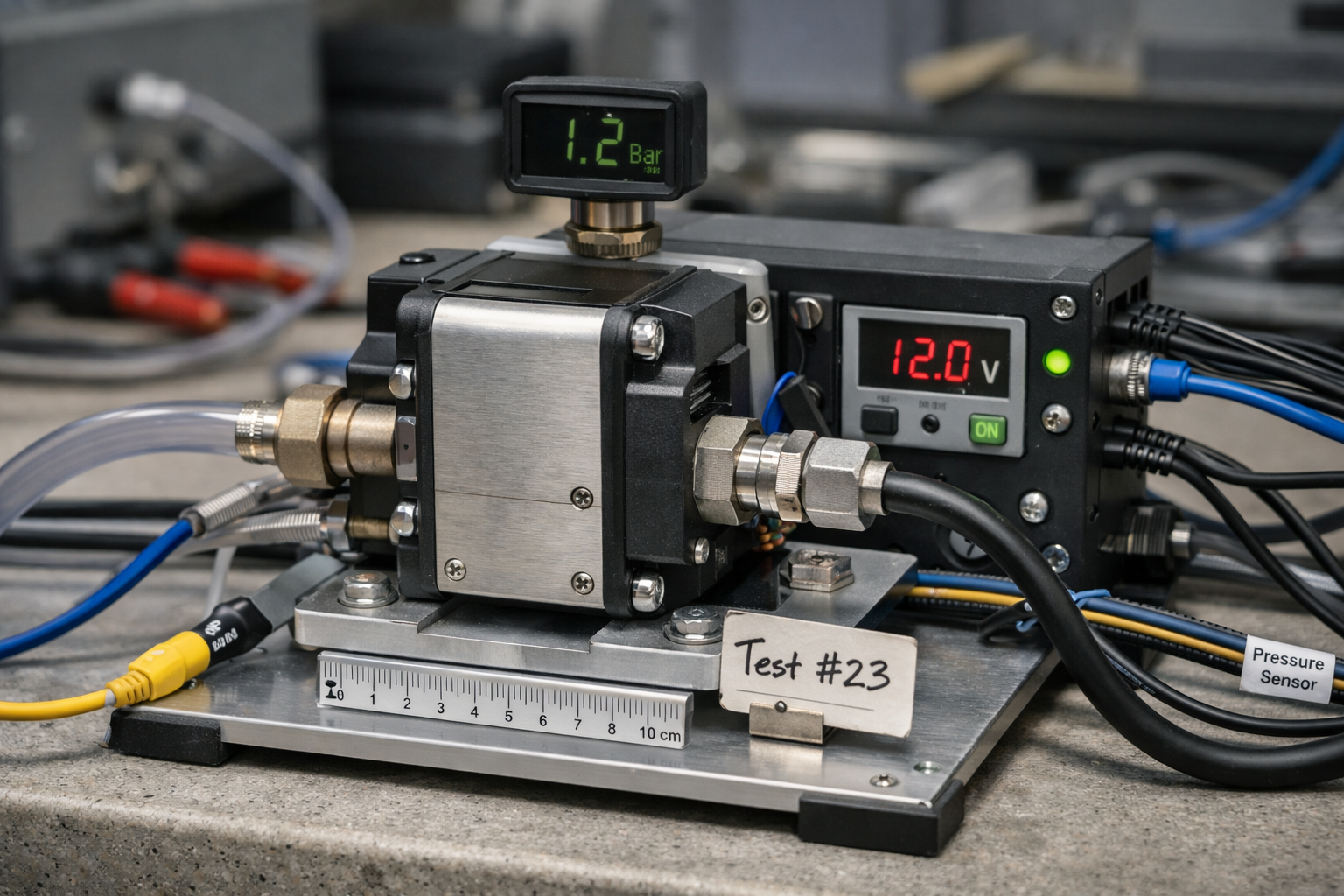

Challenges (What was going wrong)

terminal voltage can dip below the controller’s undervoltage threshold, causing shutdown.

The critical factors are rate capability, internal resistance distribution, and controller threshold

Solution (How PKNERGY engineered it)

PKNERGY proposed a dedicated high-rate Li-polymer pack (LP601545) aligned to the customer’s electrical profile and mechanical envelope.

Our goal was stable startup behavior and production consistency—not just meeting a paper spec.

- Spec confirmation

- Sample iteration support

- QC criteria proposal

- Integration note

Key Specifications (LP601545)

Results (What improved)

- More reliable startup behavior: stable performance during motor start and load changes.

- Reduced integration complexity: compact form factor helped avoid housing redesign.

- Production-ready consistency: QC checkpoints improved confidence for repeatable delivery.

- Project progress: moved from prototype evaluation into production integration.

PKNERGY understood our surge load profile and delivered a pack that stabilized the behavior and reduced trial-and-error.”

More Photos (Optional)

Add as many images as needed. Duplicate the cards below and replace the URLs.

FAQ — Common Questions

Our engineers will propose an optimized, production-ready solution.

Post time: Dec-30-2025